Control viral and bacterial problems in one application with

VIBREX AGRICARE.

Need innovative food, water and horticultural treatments?

VIBREX AGRICARE FOR LIVE POULTRY

Antimicrobial Intervention System Poultry Growing & Breeding

Egg Industry

For many years, intensive growing facilities have been searching for an effective and versatile biocide that rapidly destroys all types of microorganisms and provides maximum employee and environmental safety. Biosecurity has become an integral component in the management of all intensive growing facilities to ensure improvements in mortality rates and health of animals.

Vibrex is a broad-spectrum biocide that can safely be used around live animals for the control of airborne, waterborne and hard surface microorganisms. This flexible and versatile product has many applications ranging from the fogging of poultry sheds for the control of airborne pathogens to reducing biofilms and waterborne pathogens in animal drinking water.

Vibrex is a colourless, odourless liquid, non-toxic, non-corrosive and non-flammable. It is a wide spectrum bactericide, fungicide, viricide and algaecide, to be used as a disinfectant in many applications involving food chain products.

How does it work?

No other commercial biocide exists which is a “molecular free radical”. Chlorine dioxide has an odd number of electrons and desperately seeks reactants that are electron donors. As a result, Vibrex works via oxidation and not chlorination. This means that Vibrex does not produce chlorinated compounds and has limited reactions with organics, improving the effectiveness of the biocide in the presence of organic matter.

The reactive mechanism of Vibrex means that organisms cannot develop a resistance to the active ingredient.

This, together with the non-formation of carcinogenic chlorination by-products and non build-up of toxic organic or inorganic by-products like quaternary ammonium compounds, provides a safe and effective biocide that may be used around live animals destined for human consumption.

Application Areas

To be utilised in the treatment of sheds, coups, hatcheries and all hard surface areas to act as a total surface disinfectant. The destruction of surface microflora will aid in the prevention and spread of communicable disease. Consistent treatment of animal drinking water will aid in the prevention and spread of water borne viruses, bacteria and protozoa. Water treatment may be extended to cooling waters for the control of biofilms and Legionella bacteria.

Consistent treatment of facilities via fogging will impede the spread of air-borne pathogens and infection whilst remaining harmless to live stock. Treatment via the atmosphere is utilized as a vehicle to act as a ”respiratory tract infection inhibitor” and improve the biosecurity of facilities whilst animals are present. Treatment of fresh eggs with Vibrex will aid in suppression of surface contamination and reduction in E.coli count.

Exotic Diseases

Exotic avian diseases lead to epidemics, high mortality rates and devastating costs to the poultry industry.

Vibrex is capable of inactivating lipid-enveloped viruses such as Avian Influenza. Furthermore, Australian research by RRIDC has demonstrated chlorine dioxides ability to inactivate the non-enveloped viruses of Newcastle disease and Infectious bursal disease. Vibrex is capable of destroying a broad spectrum of microorganisms including bacteria, fungi, viruses and protozoa. It is able to destroy both bacterial and fungal spores.

Vibrex Antimicrobial Intervention Program

The Key to Product Safety and Quality

Vibrex is the ideal solution that can be applied into all facets of the Antimicrobial Intervention Program due to its flexibility and versatility.

Control viral and bacterial problems in one application with VIBREX AGRICARE.

Sanitation and Disinfection

- Hard surface sanitation of equipment and facilities

- Disinfection of facilities

- Control of airborne pathogens and inoculum

Water Treatment

- Disinfection of incoming and makeup waters

- Sanitation and disinfection of recycled waters

- Removal and control of biofilms in water distribution systems

- Disinfection of wastewater

Product Decontamination

- Reduce microbial loadings on surface of product or produce

- Addition to ice in contact with produce

- Improve shelf life and freshness of product

- Reduce risk from presence of human pathogens

Odour Control

- Capable of reducing many offensive odours

- Eliminate odours by controlling microbial source.

Benefits of Vibrex

- Broad spectrum biocide, effective against all bacteria, fungi, virus, algae and protozoa.

- Effective against spore forming microorganisms

- Effectively controls and removes biofilms

- Low concentration and contact times required

- Classified as a non-rinse food grade sanitiser

- Works over a broad pH range

- Does not form chlorinated by products including THMs

- Minimal effect on biocidal efficacy due to organic loadings

- Easily applied by fogging, spraying, dosing through existing CIP systems

- Non dangerous goods classification

- Biodegradable and safe to the environment

- Negligible corrosivity at recommended rates

- Micro-organisms unable to develop a resistance to the chemical

- Effective against human pathogens including Listeria, Salmonella and E.coli

Treating poultry drinking water with chlorine dioxide

Why should poultry drinking water be treated?

Water is an integral part of all physiological functions, especially digestion and nutrient absorption. As such, poor quality water can have a significant impact both economically and for the health of the bird.

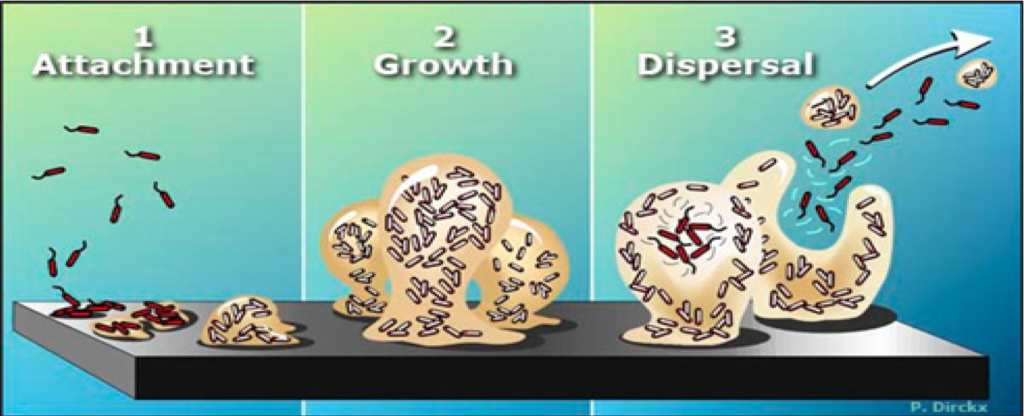

The water the birds drink is often contaminated with a range of harmful pathogens. Over time these pathogens organise into biofilm, which is a protective layer that allows the microorganism to reproduce and better defend themselves against attack.

The biofilm then becomes entrenched, which ultimately leads to the birds consuming water that is infested with harmful microbes that inhibit their growth and increase the risk of disease (such as avian influenza).

How can the quality of poultry drinking water be improved?

The quality and safety of poultry drinking can only be improved by eliminating the biofilm that is inevitably present in untreated, static water. Removing the biofilm is crucial as it protects harmful pathogens (like the avian influenza virus) from damage and allows them to proliferate. Commonly utilised sanitisers like hypochlorite aren’t effective at removing biofilm as they only attack the external surface.

Chlorine dioxide is different however, as it is a gas that is dissolved in water. This means that it can penetrate through the biofilm and attack the base of the structure, which results in the destruction of the whole matrix.

It is also highly selective, so it will only react with organic material and not nitrogenous compounds. Consequently it will leave a residual within the water for a long period of time, ensuring that the birds remain healthy and free of disease.

Figure 1: Poultry drinking water. The quality of the drinking water has been shown to have a significant impact on the growth rate and general wellbeing of the birds.

How is chlorine dioxide applied?

Chlorine dioxide can be administered to poultry drinking water in one of two ways. The first is by mixing up a chlorine dioxide solution manually and adding it to a storage tank. This method is more suitable to trialling purposes as it is labour intensive. The second is completely automated, with a dosing system delivering a controlled amount of chlorine dioxide into the bird’s drinking water.

Installing an automated dosing system is the preferred option as it has a number of engineering controls to ensure that the correct concentration is routinely delivered.

The concentration can also be easily adjusted if required, and once set-up it will continue to operate effectively without any manual supervision. Finally, it mixes the precursor chemicals in the correct ratio automatically, so chemical efficiency is maximised.

Why choose chlorine dioxide?

- It is capable of destroying a wide range of bacteria, viruses (including avian influenza), fungi and spores

- It improves the health of the poultry, leading to faster growth rates

- It is the only chemical capable of completely removing biofilm as it is present as a gas in the water, which allows it to penetrate into the biofilm and attack it at the point of attachment

- Unlike hypochlorite it does not require tight pH control (effective between a pH of 4-10)

Remains highly effective in turbid, high organic load water - It is effective at very low concentrations (approximately 0.5ppm), which ensures that it is both cost-effective and safe to use

- It is highly selective so it maintains a residual effect long after disinfection

- Unlike hypochlorite, it will not form carcinogenic by-products like THM’s.

- It is non-corrosive

Can oxidise taste and odour causing compounds, as well as manganese and iron

Figure 2: Biofilm formation. Destroying disease harbouring biofilm is essential for healthy and clean water.

Want a trial? Order a FREE sample*? T&C’s apply. *(Not available for Biochar and Vibrex)