Control viral and bacterial problems in one application with

VIBREX AGRICARE.

Need innovative food, water and horticultural treatments?

VIBREX AGRICARE FOR DAIRY FARMS

Antimicrobial Intervention System – Dairy Farms and Milking Sheds

For many years, the agricultural industry has been searching for an effective surface sanitiser that rapidly destroys all types of microorganisms and also provides maximum employee and environmental safety. Likewise, the dairy industry has been seeking a broad-spectrum biocide, that can safely be used around dairy herds and leaves no toxic residues.

Vibrex is a colourless, odourless liquid; non-toxic, non-corrosive and non-flammable. It is a wide spectrum bactericide, fungicide, viricide and algaecide, to be used as a disinfectant in many applications involving animal facilities, and food and beverage processing areas.

Chlorine dioxide provides a single solution for maintaining cleanliness in all areas of dairy farming. Vibrex can be used to sanitise animal confinement facilities, milking equipment and provide the active ingredient in pre and post teat dip solutions.

How does it work?

No other commercial biocide exists which is a “molecular free radical”. Chlorine dioxide has an odd number of electrons and desperately seeks reactants that are electron donors, unlike chlorine, which adds or substitutes a chlorine atom to the reactive substance, hence the term ‘chlorination’. Rather, Vibrex works via oxidisation. This means that Vibrex does not produce chlorinated compounds, and regardless of concentration or contact time, will work immediately.

The reactive mechanism of Vibrex means that organisms cannot build resistance to the active ingredient. Vibrex attacks the microorganism by oxidation of the cellular membrane components, interfering with metabolic function and causing cell destruction.

This, together with the non-formation of carcinogenic chlorination by-products and non build-up of toxic organic or inorganic by-products like bromates gives it the least environmental impact of any biocide in use today.

Where can Vibrex be applied?

- As a hard surface sanitiser to control bacteria, fungi and viruses in animal confinement facilities.

Sanitising feed stalls and troughs. - Treatment of water supplies and animal drinking water to remove unwanted aquatic pathogens.

- Vibrex has been utilised as an active ingredient in pre and post teat dips for the treatment and control of Mastitis causing bacteria.

- Milking equipment can be sanitised with Vibrex by using standard CIP systems to control human pathogens including Listeria and E.coli.

- Removal of unwanted odours by controlling odour causing bacteria.

Advantages

- Effectively reduces Mastitis causing bacteria including Staphylococcus aureus and Streptococcus agalactiae.

- Rapid knockdown of human pathogens including Listeria, E.coli and Salmonella.

- Unlike chlorine, organic matter does not inactivate Vibrex rapidly.

- Chlorine dioxide is approved by ANZFA and by AQIS as a food grade sanitiser requiring no rinse.

- Vibrex is less corrosive than chlorine based products.

- Removes surface microflora without toxic residue.

- Low usage rates, easy to handle and safe to use.

- Effectively kills spores on contact particularly in water systems.

- THMs (trihalomethanes) and organic chlorides are not formed when using Vibrex.

- Vibrex is approved by the APVMA as a sanitiser for the control of bacteria in animal confinement facilities.

Vibrex Antimicrobial Intervention Program

The Key to Product Safety and Quality

Vibrex is the ideal solution that can be applied into all facets of the Antimicrobial Intervention Program due to its flexibility and versatility.

Control viral and bacterial problems in one application with VIBREX AGRICARE

Sanitation and Disinfection

- Hard surface sanitation of equipment and facilities

- Disinfection of facilities

- Control of airborne pathogens and inoculum.

Water Treatment

- Disinfection of incoming and makeup waters

- Sanitation and disinfection of recycled waters

- Removal and control of biofilms in water distribution systems

Product Decontamination

- Reduce microbial loadings on surface of product or produce

- Addition to ice in contact with produce

- Improve shelf life and freshness of product

- Reduce risk from presence of human pathogens

Odour Control

- Capable of reducing many offensive odours

- Eliminate odours by controlling microbial source.

Benefits of Vibrex

- Broad spectrum biocide, effective against all bacteria, fungi, virus,

- algae and protozoa.

Effective against spore forming microorganisms - Effectively controls and removes biofilms

- Low concentration and contact times required

- Classified as a non-rinse food grade sanitiser

Works over a broad pH range - Does not form chlorinated by products including THMs

- Minimal effect on biocidal efficacy due to organic loadings

- Easily applied by fogging, spraying, dosing through existing CIP systems

- Non dangerous goods classification

Biodegradable and safe to the environment - Negligible corrosivity at recommended rates

- Micro-organisms unable to develop a resistance to the chemical

- Effective against human pathogens including Listeria, Salmonella and E.coli

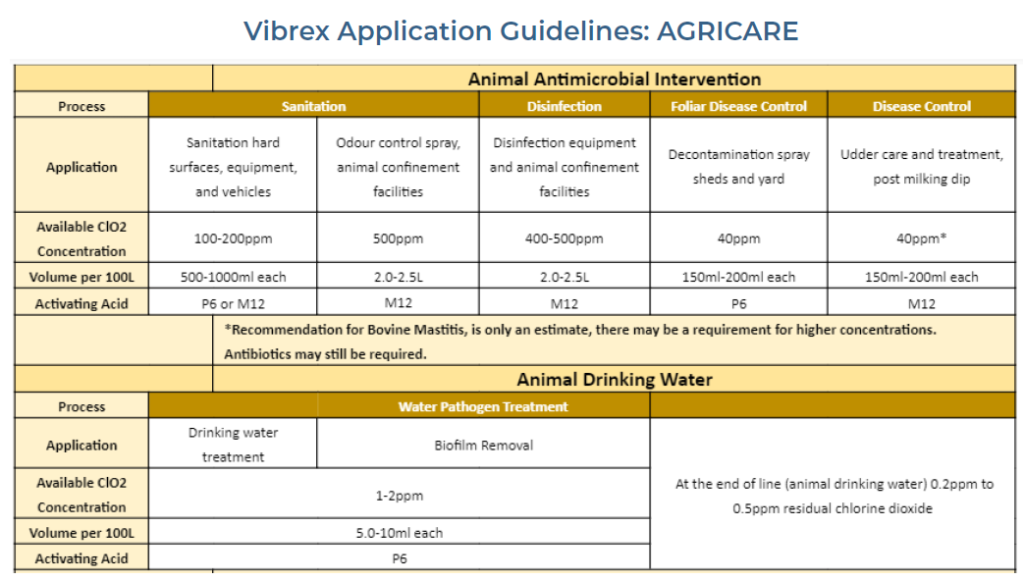

A brief Methodology is outlined below:

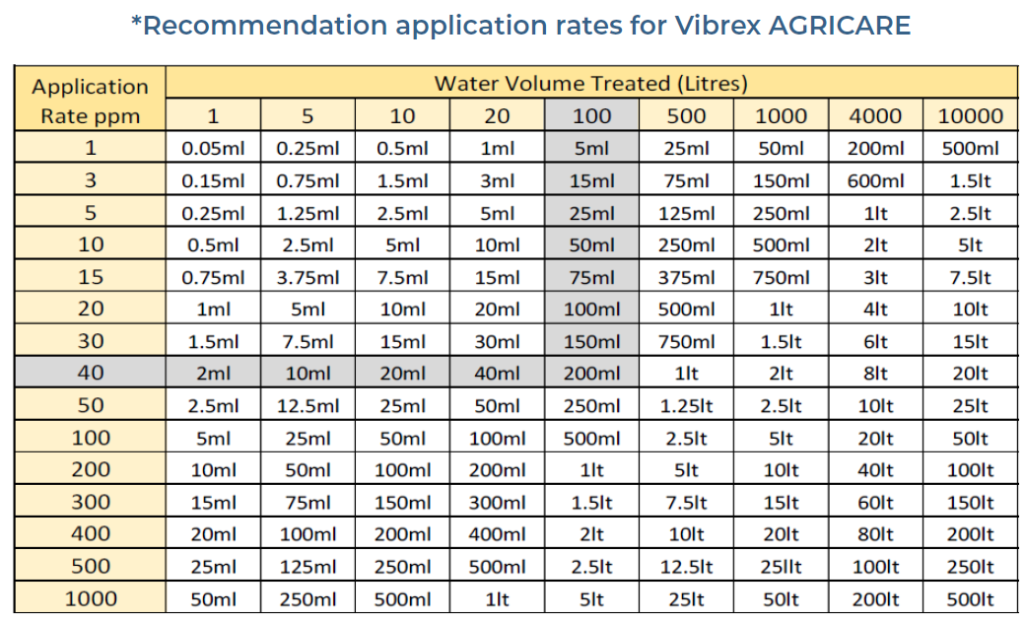

- See Chart above and volume of water requiring treatment before determining dosage rates

- To prepare sanitation solution please mix in a measuring jug at the above chemical rates – 1:1 for the Activator and Vibrex solution

- Slightly agitate the solution and let it set for at least 10 minutes to completely activate the Chlorine Dioxide

a. Safety Disclaimer – Minimise exposure and use suitable respiratory equipment as a small portion of gas will be

produced during this activation - Add the Activated solution to the water requiring treatment (e.g. For drinking water a 100L tank requiring 1ppm would need an activated solution containing 5ml Activator & 5ml Vibrex)

- Agitate final solution and record residual concentration after at least 5 minutes

- Use a Grayson certified Photometer or Low-level test kit to check residual concentration which should be sitting between indicated range in table (Contact Grayson Australia if assistance is required for use of Testing kit)

- Always recalibrate against the test kit reading to ensure adequate sanitation. If concentration is too LOW – use additional Activator when mixing solution. If that does not help the residual – use a higher rate of both chemicals until residual is reached.

- If water is not turned over within two days – repeat steps 1-7 to re-treat the water to ensure adequate sanitation.

Want a trial? Order a FREE sample*? T&C’s apply. *(Not available for Biochar and Vibrex)